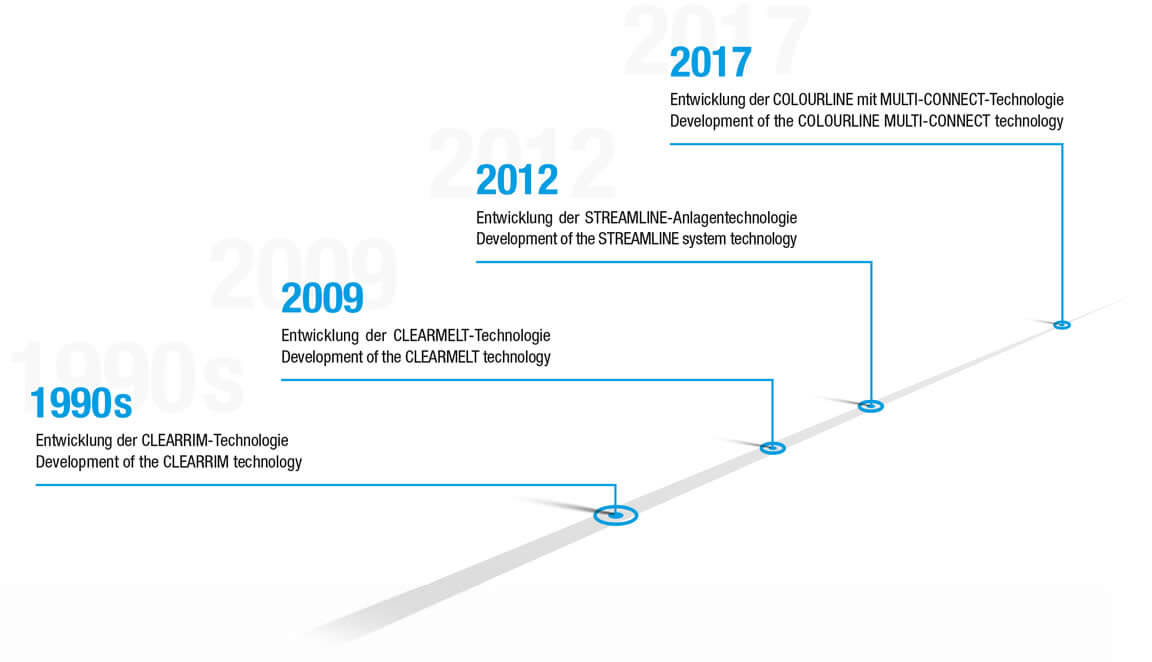

CLEARMELT plant technology

Hennecke CLEARMELT production lines offer users an equally innovative and efficient plant concept for the effective finishing of support elements by coating with transparent or colored polyurethane or polyurea systems in the RIM process. In this way, users get a scratch-proof, resistant and functional surface structure for decorative parts in the automotive industry, the consumer goods industry and for countless other decorative elements. Furthermore, thermoplastic molded parts can be directly combined with decorative films, functional elements or veneer elements. Finishing using transparent or colored polyurethane or polyurea systems can be achieved in the same production cell.

Hennecke – the specialists for surface finishing of decorative components

Hennecke's CLEARRIM technology offers an innovative concept for efficient production of parts with high-quality and functional surfaces. It focuses on the use of a thin layer of polyurethane or polyurea, through which thermoplastic support elements or support elements with natural surfaces are effectively finished. This allows users to achieve scratch-proof, resistant high-quality surface structures for decorative parts in the automotive and furniture industries or for countless other decor elements. Moreover, CLEARRIM can be perfectly combined with other processing techniques. This is very well illustrated by a further development of the process based on the cooperation between Hennecke and ENGEL Austria in the field of mechanical engineering: The CLEARMELT technology. Through this cooperation thermoplastic moulded parts are manufactured in the injection moulding process and coated in the subsequent process step. The direct integration of decorative foils or veneer elements is advantageous. In this regard, the transparent polyurethane or polyurea systems are implemented in the same production cell. A specially developed interface supports the integration system in an existing injection moulding machine. Finishing with coloured polyurethane systems is an additional development stage. Through use of different colours and effect pigments, such as metallic flakes, in terms of design freedom, now there are virtually no limits imposed on the user. Here, the COLOURLINE can demonstrate its full potential.