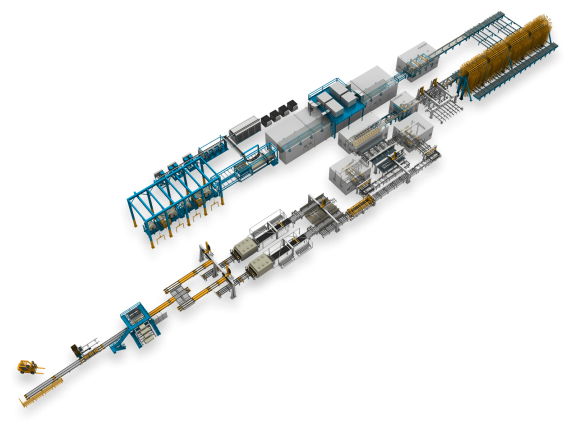

PANELMASTER FLEX

Continuous sandwich panel lines for producing polyurethane insulating boards with flexible facings are primarily used for heat insulation of house and industrial roofs as well as wall, floor and ceiling insulation. Trust in the production system of a global leader! Continuous panel plant technology from Hennecke-OMS allows for large-scale, high-speed production of top-quality insulation boards with a variety of flexible facings, thicknesses and edge profiles. Our comprehensive system solutions produce packaged and stacked end products at high speed due to the use of process and handling systems. Thanks to our comprehensive product portfolio in this special segment of insulation board production, Hennecke-OMS has all the necessary equipment at its disposal for each stage of the process, from the reaction technology and handling, up to the packaging and stacking of the finished boards. This naturally includes our expert knowledge of the process chain for handling raw materials as well as comprehensive tank farm solutions. Of course we are also in a position to implement safety design, production planning and process technology for production plants with pentane, to ensure safe operation at all times.

With a typical production capacity of up to 4300 square meters per hour (50 mm thickness, 1200 mm board width at 60 m/min), the advanced plant concept of the PANELMASTER FLEX covers a wide range of applications. Along with offering practical standardized plants, Hennecke-OMS supports tailored solutions to meet individual customer requirements. Users of the PANELMASTER FLEX are impressed by the plants’ easy handling and helpful assistance systems.

Unwinding and preheating section

The PANELMASTER FLEX production line begins with equipment designed to manage and prepare rolls of flexible substrate for the foaming and lamination process. Upper, lower and side unwinders handle the rolls of paper, foil, film or other flexible substrates as they are unrolled, heated and put into the correct position before foaming.

The unwinding and preheating section usually includes the following parts:

- Double unwinding unit

- Web control accumulator

- Preheating unit

Mixing and metering

Hennecke-OMS supplies the complete equipment for the efficient metering, storage, feeding and monitoring of raw materials and additives. The metering units are responsible for the homogenous mixing of the reactive components polyol and isocynanate, as well as various additives (e.g. catalysts, blowing agents, curing agents, flame retardants). Hennecke-OMS panel production lines rely on a well-planned arrangement of individual units and state-of-the-art machine components. This guarantees the customer a uniform and fine cell structure and an efficient raw material yield, leading to optimal foam properties and significant raw material savings.

The raw material dispensing equipment, or wet part, usually comprises the following parts:

- Metering units

- Component blending and gas loading system

- Temperature and mass flow control

Foaming and lamination

The foaming and lamination section represents Hennecke-OMS’s accumulated expertise in high-pressure polyurethane processing. It is the essential part of the high-speed panel production line, where polyurethane foam is dispensed between the two flexible facings to create laminated insulation boards with the desired properties and thickness.

This section usually comprises the following parts:

- Foaming portal

- Mixhead

- Laydown table

- Laminator (double-belt conveyor)

Cooling and post-processing section

Our post-processing equipment for insulation boards with flexible facings ranges from single and multi-disc crosscut saws to automated handling systems for panel cooling, side trimming, edge profiling, stacking and packaging of the final product.

The cooling and post-processing section is usually made up of the following parts:

- Flying crosscut saw

- Cooling unit

- Emergency stacker

- Longitudinal trimming and profiling unit

- Multi-blade cutting unit with direct-pass-through functionality

- Transversal profiling unit

- Turning unit (flipper)

- Wire cutting unit

Stacking and packaging section

The fully automated packaging section is designed to produce variable stacks of boards and to wrap these stacks into packs, which are then put together to form a combination of multiple packs.

This section usually includes the following parts:

- Pack preparation area

- Shrink foil packaging unit

- Package stacker and turning unit

- Wrapping systems

- Foot block insertion

- Double pack stacker

Plant control system

The PANELMASTER FLEX automation system uses state-of-the-art, computer-aided systems that ensure maximum operational reliability and enable fast and largely automated product changes. The intuitive visualization provides optimum support to the plant operators with these tasks.

The plant control system usually comprises the following parts:

- “Wet-end” control

- “Dry-end” control

- Pentane Process Technology (PPT) concept

Tank farm equipment

Hennecke-OMS can also provide the latest, state-of-the-art equipment and technology for complete turnkey tank farm solutions. Our global experience forms the foundation of highly-efficient concepts in consideration of different local rules and regulations.

The tank farm equipment usually includes:

- Tank storage facility for polyol, isocyanate and additives

- Tank storage facility for pentane