Sandwich panel roll forming lines

Hennecke GmbH Roll Forming Technology provides the right machine technology for surface and edge profiling in the continuous production of high-quality sandwich composite elements with a core of polyurethane or mineral wool and metal facings. This fits perfectly into the existing plant concept of the PANELMASTER continuous sandwich panel lines from Hennecke-OMS. The Hennecke GROUP is therefore one of only a few companies worldwide with overall system competence and can therefore offer its customers complete solutions for everything ranging from sheet metal decoiling to packaging the finished stack. A distinctive characteristic of the high-performance sandwich panel roll forming plants from Hennecke GmbH Roll Forming Technology is that they are extremely rigid. This gives our customers the security of being able to work with the lowest tolerances. The plants are highly precise and have an excellent level of repetition accuracy. The high production speed in combination with very short set-up times ensures optimum plant efficiency. State-of-the-art control technology and high-quality hydraulic components ensure that everyday production runs smoothly.

Areas of application

Sandwich panel roll forming plants from Hennecke GmbH Roll Forming Technology are available for the following applications:

- Insulation roof panels

- Insulation thermal walls

- Insulation cold storage elements

- Insulated industrial sectional doors

- Garage sectional doors (with and without finger protection)

- Sandwich fire safety elements

Depending on the layout of the plant, the following primary materials can be used:

- Galvanized sheet steel with a thickness of at least 0.4 millimetres

- Aluminium with a thickness of at least 0.3 millimetres

- Coated and painted primary material

- High-strength primary material grades

- Primary materials with and without protective foil

Highlights and features

Sandwich panel roll forming plants from Hennecke GmbH Roll Forming Technology come equipped with the following features right from the factory:

- Coil loading

- Strip preparation

- Strip connection with automatic gluing machines

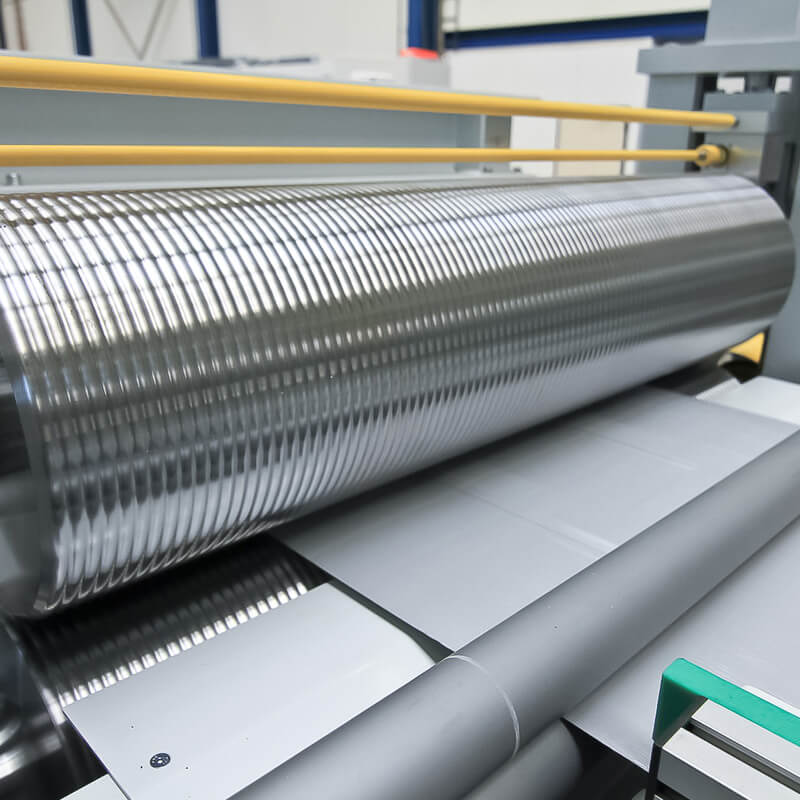

- Profiling area for edge and surface profiling, surface lining, surface structuring

- Integration of punching and forming processes, for example panel embossment for sectional doors

Get the most out of your production! We offer real distinctive features:

- High precision

- Excellent repetition accuracy

- Very high production speed

- Shortest set-up times

- Optimum plant efficiency

- Tailor-made customer solutions

Continuous production of sandwich panels with rigid or flexible facings

The product portfolio of the PANELMASTER series from Hennecke-OMS is designed for the continuous production of top-quality sandwich panels with different facings, panel thicknesses and profiles and the option of a core structure made of polyurethane or mineral wool. With a usable width from 500 to 1200 millimeters, a panel thickness between 20 and 250 millimeters and a production capacity of up to 700 square meters per hour, the advanced plant concept covers an extremely wide range of applications. On top of this, we offer you a great number of customized solutions.