Slabstock lines from the global market leader

Slabstock foams are used when cushioning and insulating qualities combined with low weight are important. Processors who want to be competitive and conform to market requirements must be able to offer their customers high-quality products with a wide range of specific properties. Here, continuously as well as discontinuously operated slabstock systems technology from Hennecke offers the decisive advantage. The application of various technologies allows processors to achieve an extremely high degree of material yield. It is not without reason that Hennecke is the global market leader in this segment, offering a wide range of plant configurations for standard and special foams. In addition, we can also offer our customers slabstock systems technology that has been specially developed for test series and laboratory purposes.

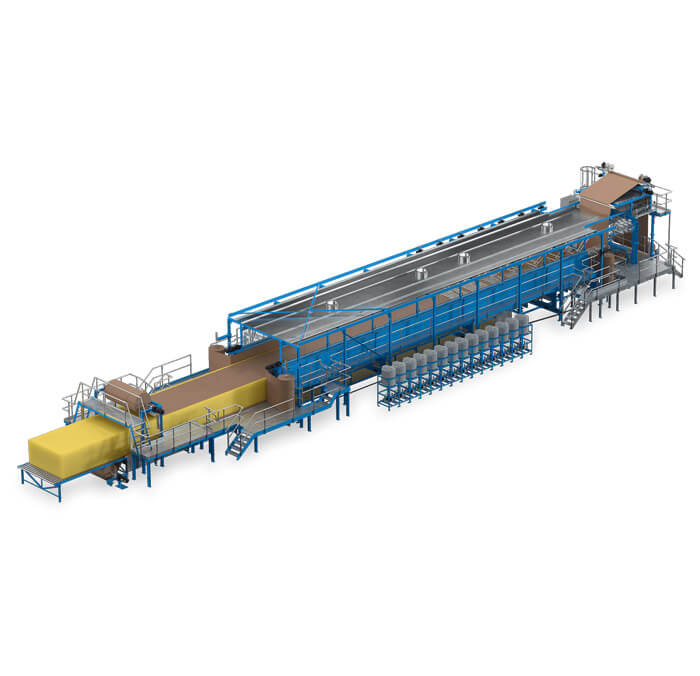

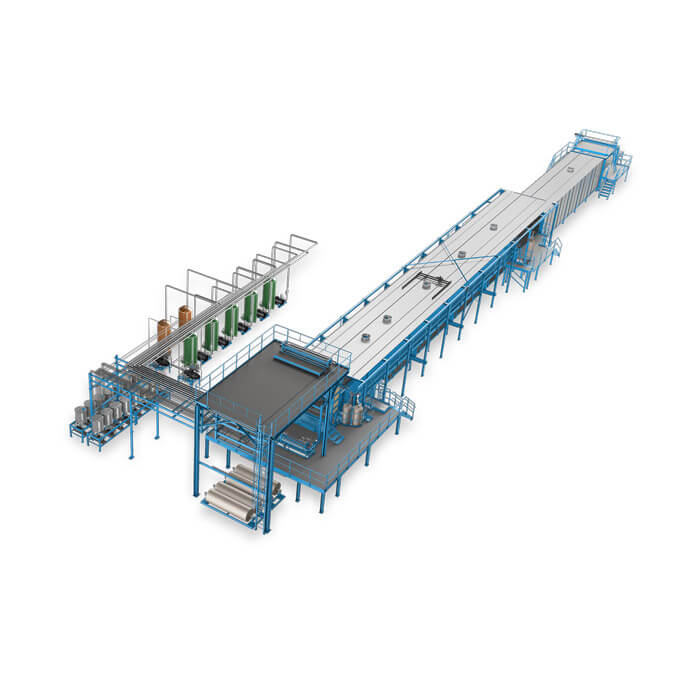

Continuous slabstock lines

Cost-efficient production of high-quality flexible foams

The combination of precise high-pressure metering and a powerful stirrer mixer makes Hennecke's continuous slabstock lines the perfect partner in the efficient processing of all commercial materials in almost all density ranges. Through the combination of various technologies exclusive to Hennecke, continuous slabstock lines are opening up a variety of prospects for the cost-effective manufacture of high-quality foams of any length, up to 2,500 mm in width and, depending on the foam type and specific density, with a height of up 1,500 mm. The Hennecke systems technology combines the individual advantages of all the well-known concepts for the continuous production of polyurethane slabstock foams and provides the processor with the highest possible quality. Thanks to its individual adaptation to market or environmental requirements, it also offers the highest degree of production flexibility for competitive production results over an extremely long period of time.

All continuous slabstock lines at a glance

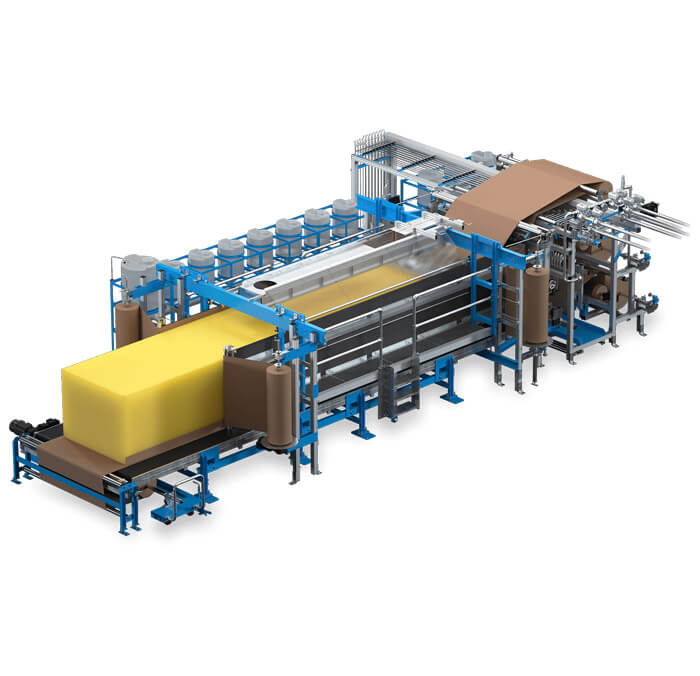

Discontinuous slabstock lines

Minimal use of space, easy start-up, flexible production

When small batches are produced or special foams such as visco-elastic foams are being made, the discontinuous production of flexible slabstock foams is often the most suitable solution. This is also true in terms of economic efficiency. Discontinuous slabstock lines made by Hennecke are very convincing because they require less invest and less space. Of course, the company also has decades of experience in discontinuous lines and only uses tried-and-tested quality components.

Laboratory systems

Slabstock systems technology for test series and laboratory purposes

Hennecke's laboratory systems are used to conduct test series for different raw materials and additive systems in continuous slabstock production. For example, a variety of test formulations can be precisely transposed to real production conditions, without interrupting the current production run or wasting a large amount of valuable raw materials.