PUR-CSM SANITARY lines

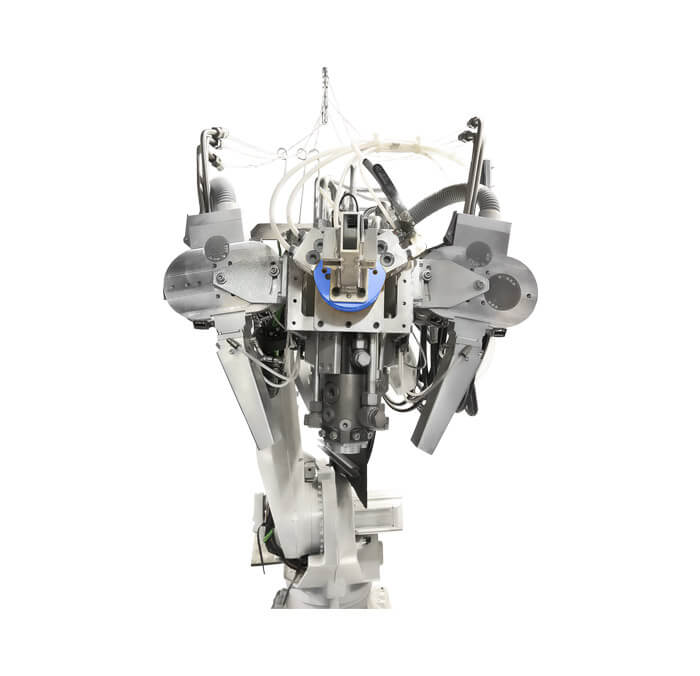

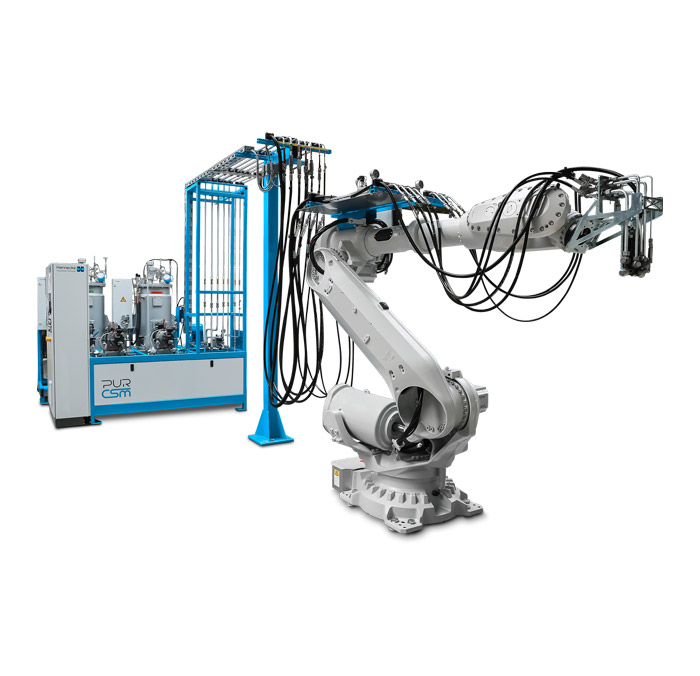

One forward-looking yet eco-friendly major application of PUR-CSM technology lies in the substitution of GFRP mouldings such as bathtubs and shower trays. Here, the use of PUR-CSM meets the most exacting demands in terms of production flexibility, reproducible part quality and material efficiency. For instance, CSM-reinforced bathtubs exhibit an outstanding thermal insulation and clearly reduced sound emissions. Moreover, the full elimination of solvents not only cuts production costs but also simplifies exhaust air system requirements substantially. PUR-CSM-SANITARY manufacturing cells are available in several designs and for various production capacities. Each line comes equipped with a TOPLINE high-pressure metering machine (a special version for sanitary applications) and state-of-the-art two-component spray mixheads. Multi-component systems and cutters for glass-fibre reinforcement are available optionally.