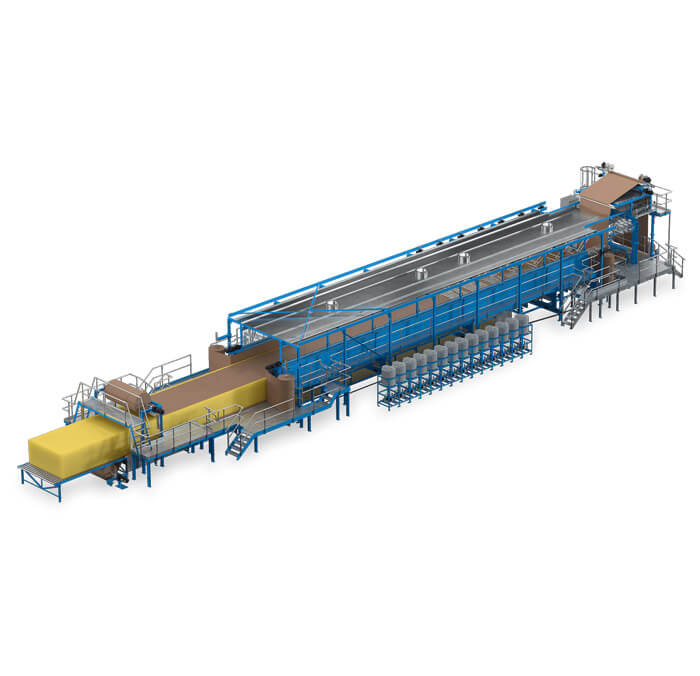

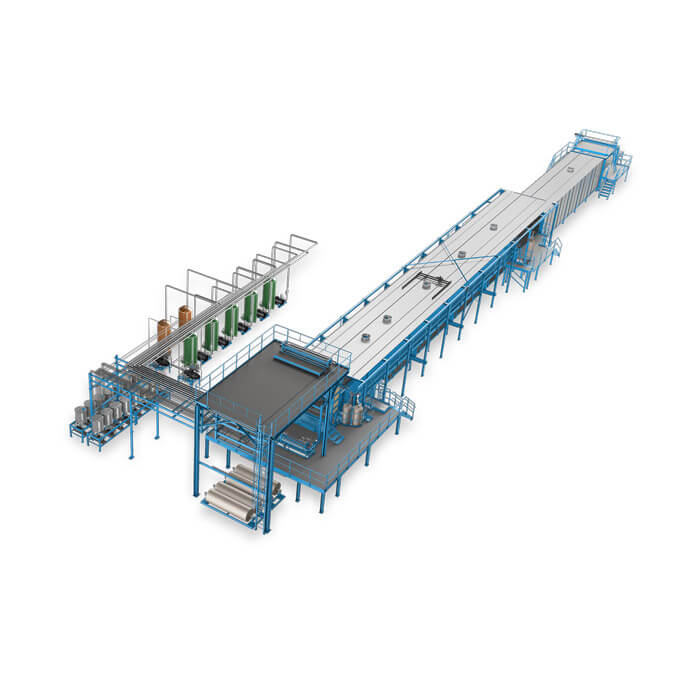

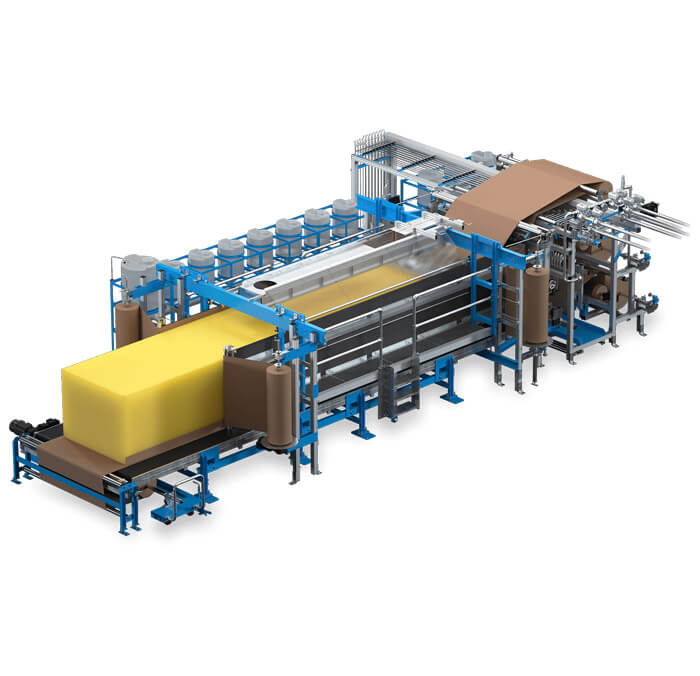

MULTIFLEX

For almost eight decades Hennecke has developed and produced high-quality plants for polyurethane processing. Hennecke is considered the market leader in the field of slabstock machinery and equipment. This know-how is reflected in the MULTIFLEX systems. The latest generation of one of the world's most renowned slabstock lines impresses processors with its attractive price-performance ratio, which – thanks to a highly efficient raw material yield, outstanding foam qualities and the state-of-the-art FOAMWARE system control – ensures a fast return on investment. Based on analyses and statements by leading slabstock foam producers and raw material manufacturers, the use of Hennecke high-pressure technology saves up to 5 percent isocyanate compared to low-pressure slabstock machines. With an annual slabstock foam production of 5,000 tonnes and an isocyanate price of EUR 3.00/kg, this corresponds to a saving of around EUR 200,000 per year. A further considerable cost saving results from the use of the proven LIQUID-LAYDOWN system together with the Hennecke rectangular process (FLAT-TOP system). 4-sided paper covering over the produced foam block – where the top rind is converted into usable foam – allows slabstock foam producers to achieve up to 5 percent higher foam yields compared to production without cover paper. And not forgetting: physical properties in terms of hardness and bulk density distribution are significantly optimized. This ensures the user a highly efficient raw material yield and the best foam quality. What is more, production can be further optimized by automating the FLAT-TOP-Systems (patented AUTO-FLAT system).