HIGHLINE MK2

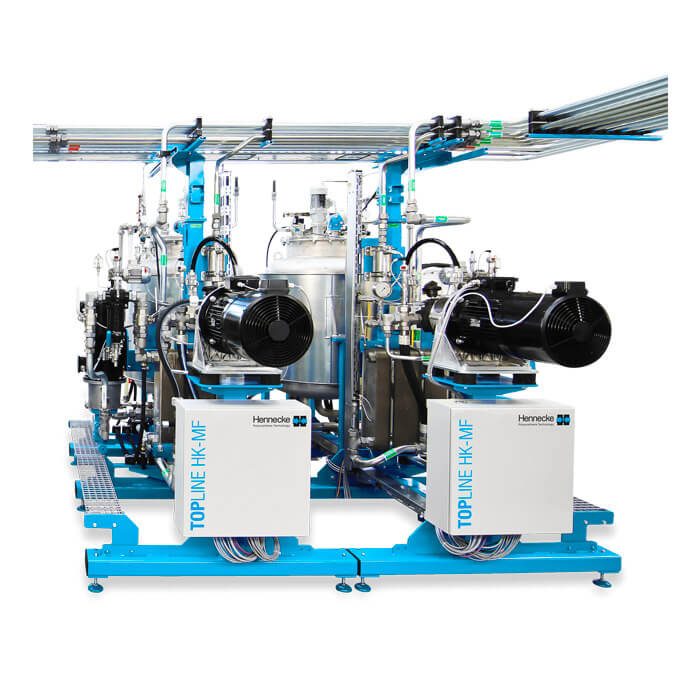

NEW Welcome to the uncompromising, multi-talented machine in Hennecke's high-pressure class - making a noticeable difference every day. The new, multi-functional model generation in the HIGHLINE series, the HIGHLINE MK2, offers users distinct advantages and sustainable innovation for the long term. The cost-efficient all-rounder in Hennecke's 'NEXT-GEN' lineup makes no compromise on mixing quality, resource efficiency, or digitalization, offering the highest quality in all its decisive elements. The HIGHLINE MK2 provides a seamless transition to a high-performance metering machine, and can be used for processing virtually all raw material systems. The compact machine can be adapted to a variety of applications thanks to a wide range of standard options.

- The HIGHLINE MK2 capitalizes on the mixheads from the top MT-A series, available in five sizes, and suitable for open shot as well as docked processing.

- In combination with the FIXJET and FLEXJET SL series from the latest Hennecke injector generation, the HIGHLINE MK2 mixhead portfolio outperforms in fulfilling all the requirements of modern polyurethane systems in terms of metering accuracy, mixing quality and service life of the components.

- The groundbreaking HX pump is significantly more pressure-resistant, quieter, and more energy-efficient than other common pump models. In addition, integrated sensor technology gives the user extensive information when required, and supports improved machine availability through predictive maintenance.

- The HIGHLINE MK2 is controlled using the latest SIMATIC platform components. The high-resolution, 12-inch premium HMI with powerful CPU is home to a completely new and intuitive visualization system: the Hennecke FOAMATIC. The operator can be sure of maximum performance and control, along with fast access for the widest range of applications in many common languages. Remote HMI allows the FOAMATIC to mirror the user interface on almost any network-compatible device with a display.

- The HIGHLINE MK2 enables connection to the Internet of Things with the FOAMATIC-IoT equipment feature. The acquisition and storage of extensive process data offers Hennecke customers unimagined possibilities for evaluation, early detection and prevention of problems, as well as predictive machine maintenance.

- The newly developed TS5evo temperature control unit and specially adapted control software play a key role in ensuring a constant raw material temperature, even with the most adverse production conditions. The desired raw material temperature is easy to set on the HMI, whilst the plant's control system works autonomously on everything else.

Just like the ECOPLUS MK2, Hennecke's Blue Intelligence technology also comes as standard with the HIGHLINE MK2, helping to make the machine significantly more energy-efficient, depending on the production scenario. At Hennecke, Blue Intelligence encompasses all the measures serving to enhance the sustainability of production systems. In the case of the HIGHLINE MK2, this includes, for example, energy use when no shot is called, the automatically determined pump lead time, and efficient pumps that are more raw material-efficient due to improved temperature management. Based on the individual production scenario, savings of up to 50% can be made.

#nextgenstore

The world's first configuration platform for high-pressure metering machines.