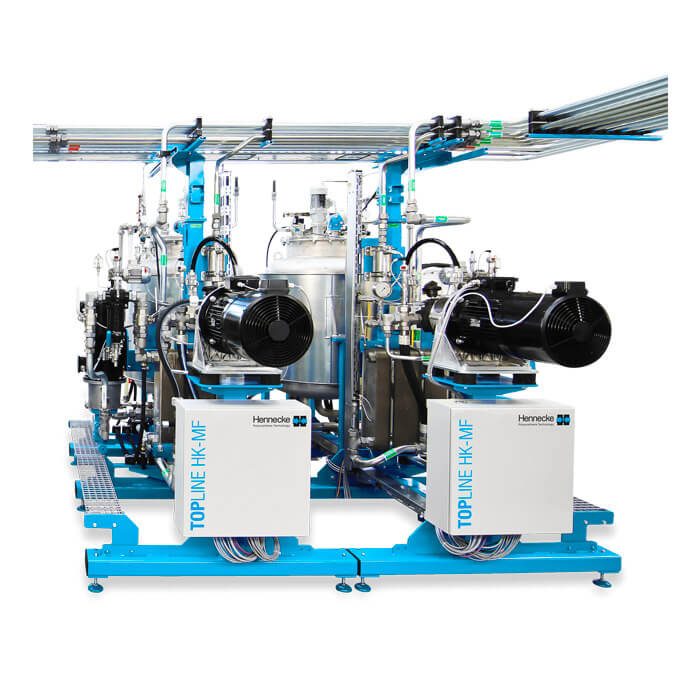

TOPLINE HK-MF

Moulded foam lines rely on a further development of the TOPLINE type series. The "HK-MF" version has been optimised to meet the specific requirements of moulded foam production and is suitable for reliably processing up to six reactive components in a plant network. Users benefit from an extremely compact machine frame that incorporates all elements of a reactive component and, compared with the classical TOPLINE, scores points because the pipework has been significantly reduced. Combined with a temperature control system in the component feed line, this ensures very precise temperature control. When using two mixheads or two injection robots, the "HK-MF" is employed as a twin module. Especially when it comes to multi-component applications with up to twelve metering lines, this means once again that a considerable amount of precious production space is saved. Apart from the efficient raw material temperature control system, HQ axial piston pumps are included in the standard scope of delivery of the WKH unit. If desired, users can opt for state-of-the-art magnetic coupling technology and other features.